For candy companies, a high-quality 3D candy mold is not just a tool for product shaping, but also a key link in improving production efficiency, creating differentiated products, and controlling costs. From market-oriented hit gummies to custom gift box hard candies for festive seasons, the appeal of 3D candy shapes and the stability of product quality directly affect end sales. The material selection, design craftsmanship, and adaptability of molds are the underlying supports that determine these core factors.

Material Matrix: Full-Range Coverage to Meet Diverse Needs

Langying Molds deeply understands the differentiated needs of different production scenarios and has built a full-range mold matrix covering food-grade silicone, plastic, and metal materials to meet diverse needs from home baking to industrial mass production. Its silicone molds, with excellent flexibility and non-stick properties, show advantages in small-scale production and creative trial production. Especially when paired with internal rigid support materials, they can maintain shape stability in medium-batch production and reduce candy molding deviations.

However, in the large-scale production scenarios of candy companies, metal molds have become the key recommendation of Langying due to their performance advantages more suitable for industrial needs. Compared with silicone materials, metal molds have more outstanding performance in thermal conductivity efficiency, structural strength, and service life, which can perfectly match the core demands of high-intensity continuous production and provide underlying guarantee for enterprises to stabilize production capacity.

Metal Molds: Core Advantage Support for Industrial Production

1. Material Stability: Ensuring Production Continuity and Food Safety

The durability of metal molds is the core foundation for their adaptation to industrial production. Langying metal molds are made of high-quality materials such as food-grade stainless steel and have passed authoritative safety certifications, avoiding the risk of harmful substance migration from the source and meeting the basic requirements of enterprises for food safety. More importantly, their excellent anti-wear ability can withstand long-term high temperature, high pressure, and mechanical impact, avoiding the deformation and aging problems that silicone molds are prone to in high-frequency use, greatly reducing production interruptions caused by mold failures, and providing reliable support for enterprises to stabilize production capacity.

At the same time, the smooth cavity surface of Langying metal molds, combined with independently developed food-grade non-stick coating technology, can significantly reduce the probability of candy sticking. The demolding loss rate is much lower than that of ordinary molds, which not only reduces raw material waste but also simplifies the cleaning process and shortens the production interval, further improving production efficiency.

2. Design Craftsmanship: Accurately Presenting Differentiated Product Ideas

In the current context of increasing homogeneous competition in the candy market, the uniqueness of product shapes is the key to breaking through the market. Relying on precise processing technology, Langying metal molds can achieve accurate reproduction of complex 3D shapes. Whether it is the facial details of teddy bear gummies, the texture layers of multi-color combined candies, or the 3D scenes with festive themes, they can be perfectly presented through optimized cavity structure and thermal conductivity design.

This accuracy stems from Langying’s in-depth exploration of the characteristics of metal materials. The excellent thermal conductivity of metals can ensure the rapid and uniform cooling of candy colloids, avoiding the shape blurring problem of silicone molds caused by uneven thermal conductivity, and ensuring that each batch of products maintains consistent detailed quality. At the same time, Langying’s flexible customized services can quickly respond to enterprises’ needs for IP co-branding and seasonal limited editions, efficiently transforming creativity into mass-producible mold solutions and helping enterprises create market differentiation advantages.

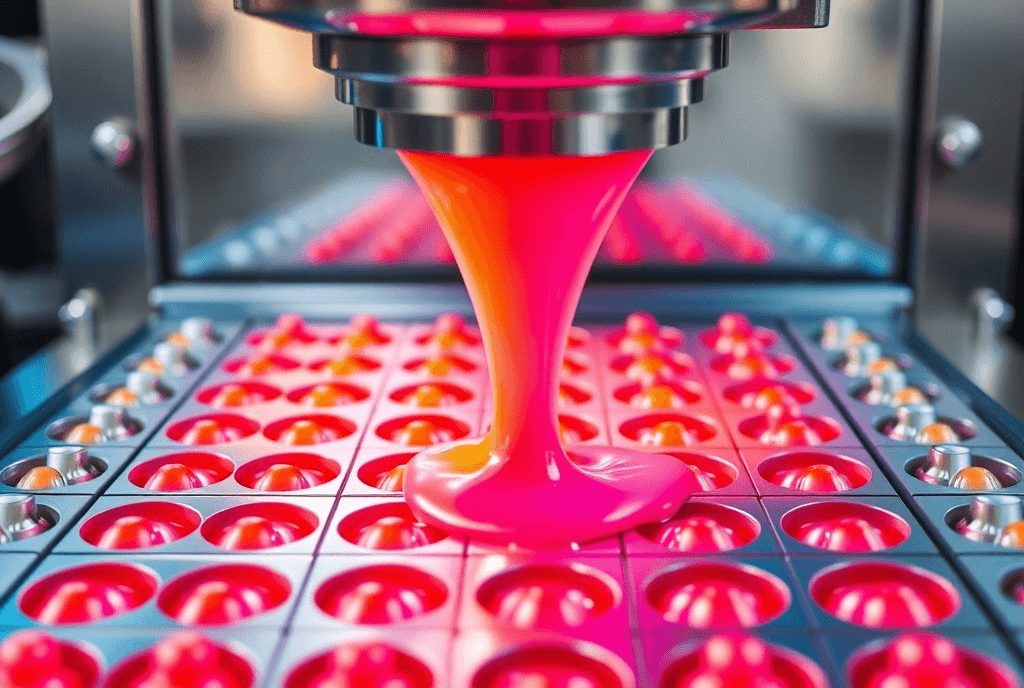

3. Production Adaptability: Seamless Connection with Automated Production Lines

The automated production lines of candy companies have high requirements for the compatibility and intelligence of molds. Langying metal molds adopt standardized size design, which can be easily connected to various candy pouring equipment without modifying the existing production lines, enabling rapid put-into-use and realizing seamless connection of the whole process of pouring, cooling, and demolding.

More notably, Langying has deeply integrated intelligent technology into the candy production system. Through temperature sensors and IoT modules, it can monitor key parameters in the production process in real time, and then automatically adjust the cooling speed and pressure through the PLC system to ensure that each batch of candies maintains consistent taste hardness and molding speed, greatly reducing rework losses caused by quality fluctuations. This “ready-to-use + intelligent control” feature is a core demand of industrial production that silicone molds are difficult to meet.

4. Cost Control: Realizing Maximization of Long-Term Profits

For enterprises, the whole-life cycle cost of molds directly affects the profit level. The service life of Langying metal molds is significantly longer than that of silicone molds, which can reduce procurement costs caused by frequent replacements. Their stable performance reduces the risks of raw material waste and order delays caused by mold problems.

In addition, Langying provides full-link services from mold design, installation and commissioning to later maintenance. The professional team regularly provides maintenance suggestions and promptly solves technical problems during use, avoiding long-term production shutdowns caused by mold failures and further reducing the hidden costs of enterprises. This “product + service” model makes the long-term cost-effectiveness advantage of metal molds more prominent.

Against the background of escalating competition in the candy industry, the quality and adaptability of molds have become an important part of the core competitiveness of enterprises. With a full-material product line to meet diverse needs, Langying Molds, relying on the all-round advantages of metal molds in stability, accuracy, adaptability, and cost control, provides reliable support for candy companies from creativity to mass production, helping enterprises achieve dual improvement in quality and profits in the “sweet track”.