In modern candy manufacturing, gummy bears, with their cute shapes and rich flavors, are beloved by consumers. With advances in technology, industrial production has gradually become the mainstream, and the combination of standardized processes and advanced equipment has made gummy bear production more efficient and consistent. This article explores the innovative application of metal candy molds in gummy bear production and provides a detailed analysis of the entire candy depositing technology process.

I. Comprehensive Analysis of the Industrial Gummy Bear Production Process

The production process of industrial gummy bears involves multiple steps, each requiring precise control to ensure the quality and flavor of the final product. The core process includes:

- Raw Material Proportioning and Gel Processing

- The basic recipe includes gelatin, sugar, water, and glucose syrup. A PLC-controlled automated weighing system can accurately measure each raw material to ensure consistent flavor in every batch. Gelatin needs to be pre-soaked before processing to fully realize its gelling properties, and then it is mixed with syrup in a vacuum cooker to form a stable gel.

- Breakthrough in Injection Molding Technology

- A servo-controlled depositing machine is used to inject the gel mixture into metal candy molds. Metal candy molds, with their excellent thermal conductivity and smooth surfaces, can quickly cool the gel mixture and maintain precise shapes, making them particularly suitable for the complex designs of gummy bears. The efficient operation of fully automated production lines significantly increases production capacity, and the standardized size of molds facilitates mass production.

- Demolding and Surface Treatment

- Food-grade release coatings are used in conjunction with metal candy molds to achieve efficient and damage-free demolding. Subsequently, the candies are shaped in a cold-air tunnel and finally coated with a layer of wax to prevent them from sticking together.

II. Core Value of Metal Candy Molds in Depositing Technology

The use of metal candy molds has greatly optimized the gummy bear production process, with several primary advantages:

- Precise Temperature Control: Metal candy molds can rapidly conduct heat and, when combined with modern temperature control systems, ensure that the gel sets evenly.

- Diverse Shape Options: Metal candy molds can accommodate a wide variety of complex designs, such as three-dimensional shapes and multi-color combinations, meeting market demands for innovative products.

- Enhanced Durability: Compared to silicone molds, metal candy molds have a longer service life and can withstand higher production intensity, thus reducing long-term operational costs.

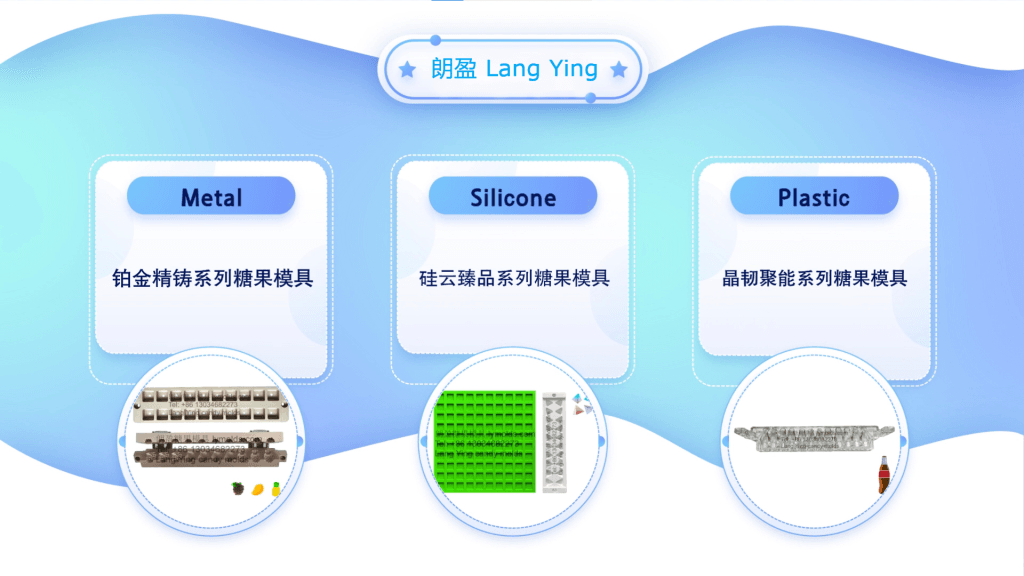

III. Lang Ying Molds: An Industry Benchmark for Candy Mold Technology

As a professional candy mold manufacturer, Lang Ying Molds continually drives the industry forward through technological innovation. Their main features include:

- Breakthroughs in Coating Technology: Lang Ying Molds develops non-stick coatings that effectively reduce demolding losses while ensuring compliance with food safety standards, thereby avoiding residue risks associated with traditional release agents.

- Customized Design Services: Lang Ying Molds offers comprehensive services from design to production, accommodating a variety of styles, including holiday-themed and co-branded molds.

- Intelligent Mold Systems: Integrated temperature sensors and IoT technology allow for real-time monitoring of mold conditions, optimizing production processes and improving product quality.

IV. Key Points for Quality Control in Industrial Production

In industrial production, ensuring the consistency of product quality is crucial, with particular focus on the following aspects:

- Environmental Parameters: Maintaining appropriate workshop temperature and humidity is essential to prevent the gel from absorbing moisture and deforming during production.

- Mold Maintenance: Regular cleaning of the molds is necessary to ensure they are in good condition, thus enhancing production efficiency and product quality.

- Ingredient Testing: Effective testing measures are needed to analyze moisture levels and gelling characteristics of the raw materials in a timely manner, ensuring the final product achieves the desired chewy texture.

Conclusion: The Fusion of Industry and Art

The production of gummy bears has evolved from home crafting to large-scale manufacturing, witnessing a technological leap in the food industry. The integration of metal candy molds and depositing technology not only enhances production efficiency but also transforms creativity into mass-produced sweet art. Companies like Lang Ying Molds are driving innovation, steering the industry towards greater precision and sustainability. As you enjoy gummy bears, consider the materials science and engineering wisdom that lies behind these delightful treats.